We are less than two weeks away from the implementation of the update to NFPA 652, Standard on the Fundamentals of Combustible Dust. Although we explained these changes in our previous blog post that you can find here, we wanted to use this article to showcase how Heneveld Industrial Group can help you stay compliant.

NFPA 652 Update

As a refresh on these upcoming changes, the first step in being compliant is to test your dust for combustibility. Remember, this step is the responsibility of you and your company to complete. Even if you believe your dust is noncombustible, you will need to have written proof of this. If your dust is proven noncombustible, this standard will not apply to you. If the dust you produce is combustible, you must then perform a DHA, Dust Hazard Analysis. These DHA’s will need to be reviewed and updated every five years.

After your DHA is performed, your facility will either be deemed acceptable to continue as is, or there may be an implementation plan you must complete to be considered compliant.

Heneveld Industrial Group Solutions

Once you receive your DHA results, Heneveld Industrial Group is here to help! Whether you need help in understanding the results and implementation plan, or you need to update your facility with combustible dust compliant products, we have the answers.

Our team will be ready to help you stay compliant and is ready to act quickly to make sure you have as little downtime as possible. Some solutions we offer include:

Vacuum Systems: as Vac-U-Max’s exclusive distributor for Michigan, we have access to the best industrial vacuums in our industry. These combustible dust vacuums are all ATEX tested and certified and meet NFPA 77 requirements, meeting the definition of “Intrinsically-Safe Systems.” When purchasing a Vac-U-Max industrial vacuum, you are receiving an entire system, not just a simple vacuum. These systems include the vacuum cover, drum, dolly, vacuum hose and cleaning tools, compressed air hose with quick-disconnect fittings, and polybag drum liners. The benefits of industrial vacuums are the power behind them to pick up any loose dust that may fall on floors, adhere to walls and ceilings or equipment, providing a quick and effective housekeeping option for your company.

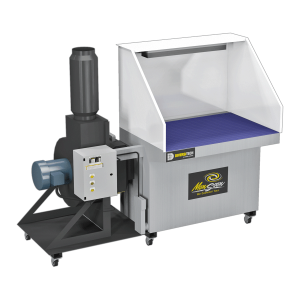

Wet Downdraft Tables: these self-contained units offer a safe solution for capturing combustible dusts. These machines pull the dust through a curtain of water mist. The dust particles will then fall to the bottom of the collector for safe removal. These units are designed for combustible dusts such as aluminum, magnesium, titanium, and from applications such as grinding & deburring, sanding & finishing, 3D printing, powder mixing and plastic dust. Additional options for these downdraft tables include side and back walls, HEPA filter kit, sludge vac, auto-wash systems, as well as the option for custom designs.

Wet Dust Collection: a few options for wet dust collection include collectors, as well as collection booths. Wet dust collectors are standalone units that can capture dust particulates as small as 3 microns. These contaminants are pulled through the blower where the particles are suspended with water. Once mixed with water, these dust particles will then drain to the bottom of the collector for safe removal. These machines are ideal for sanding, grinding and deburring applications. Collection booths add a large backdraft hood to pull the dust away from the operator.

Wet Dust Collection: a few options for wet dust collection include collectors, as well as collection booths. Wet dust collectors are standalone units that can capture dust particulates as small as 3 microns. These contaminants are pulled through the blower where the particles are suspended with water. Once mixed with water, these dust particles will then drain to the bottom of the collector for safe removal. These machines are ideal for sanding, grinding and deburring applications. Collection booths add a large backdraft hood to pull the dust away from the operator.

Heneveld Industrial Group also offers a full line of combustible dust products that include: ATEX compliant rotary air locks, explosion vents, explosion isolation valves, spark detection and extinguishment, spark eliminators, thermal and dust probes, high speed abort gates, block and dump compressed air valving, and fire suppression systems. These fire suppression systems include direct release and indirect release systems, as well as dual action systems.

Our team is ready to help you determine what systems and equipment are best for your application processes. Contact us today for any of your NFPA 652 compliancy needs.